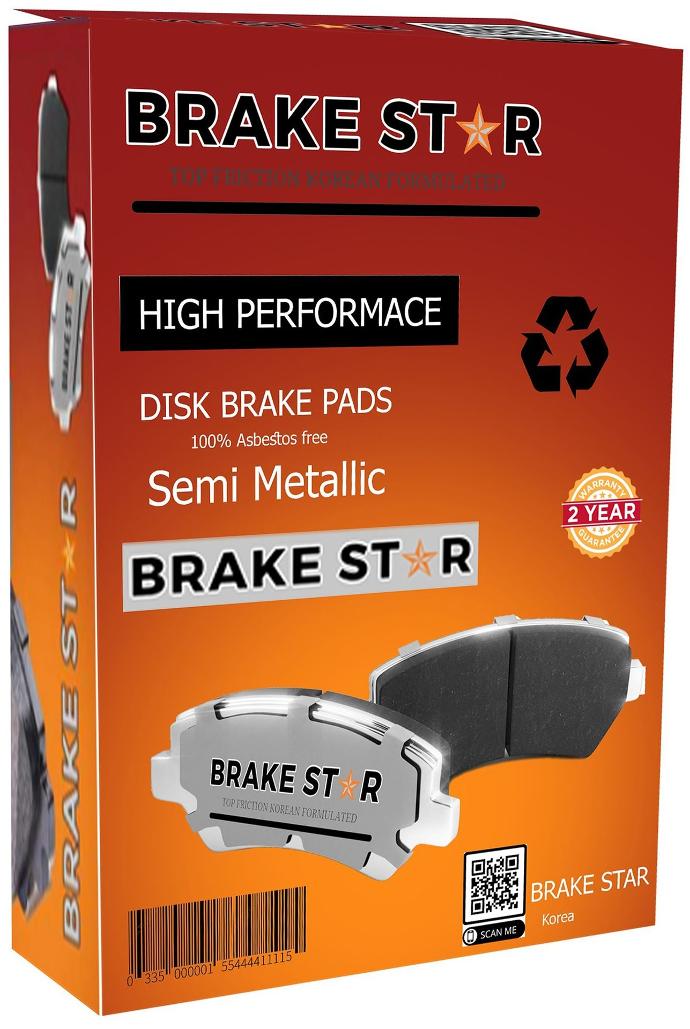

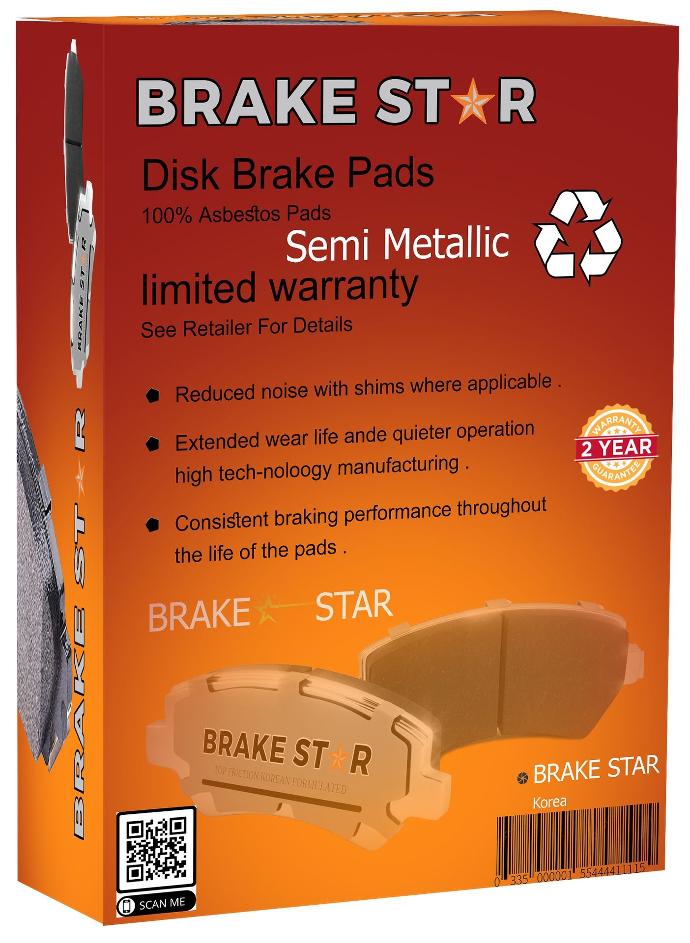

Semi Metallic

Most drivers prefer semi-metallic brake pads for performance vehicles, track driving, or as the best brake pads for towing because they give superior braking throughout a broader temperature and condition range. They are constructed of heat-conducting material, which allows them to endure higher temperatures while braking while still keeping the system cool. Semi-metallic brake pads can be louder than ceramic brake pads and are often priced between organic and ceramic brake pads.

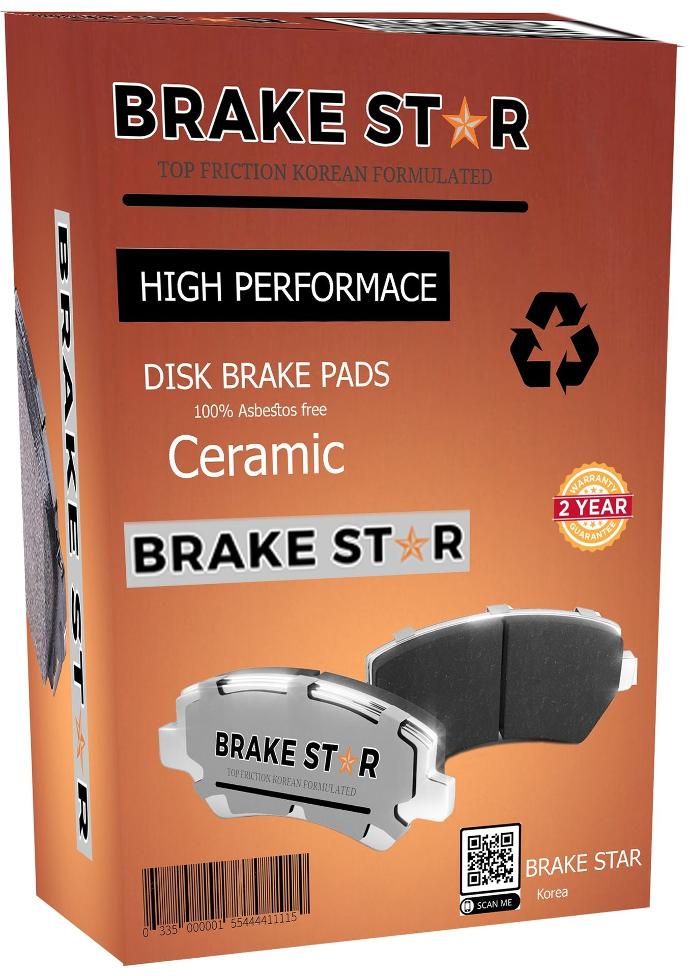

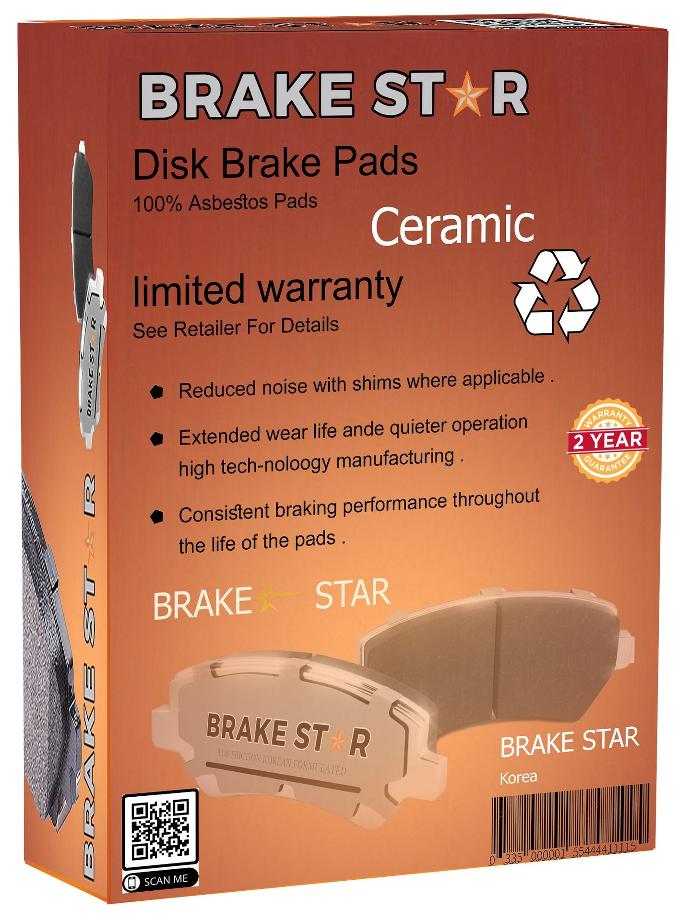

Ceramic brake pads, while quieter, are also able to handle extremely high temperatures with quick recovery, causing less damage to the brake rotors. As they wear, ceramic brake pads create a finer dust than semi-metallic brake pads, leaving less debris on the vehicle’s wheels. Ceramic brake pads typically last longer than semi-metallic brake pads, and through their lifespan, provide better noise control and less wear-and-tear to brake rotors, without sacrificing braking performance. When deciding on ceramic brake pads versus semi-metallic brake pads, bear in mind that not all vehicle makes and models are compatible with ceramic brake pads.

Semi Metallic

While ceramic brake pads are quieter, they can also withstand exceptionally high temperatures with fast recovery, resulting in less damage to the braking rotors. Ceramic brake pads produce finer dust than semi-metallic brake pads when they wear, leaving less debris on the vehicle's wheels. Ceramic brake pads often last longer than semi-metallic brake pads and provide superior noise management and reduced wear-and-tear on brake rotors during their lifetime, without losing braking performance. When picking between ceramic and semi-metallic brake pads, keep in mind that ceramic brake pads are not compatible with all vehicle makes and models.

The features of brakes can vary depending on the type of brake system, but some common features include:

Feature One

Power-assisted braking: Many modern vehicles are equipped with power-assisted braking systems that apply hydraulic or pneumatic pressure to assist in the braking process. This feature allows for easier and quicker braking.

Feature Two

Brake force distribution: Advanced brake systems can distribute the braking force proportionally between the front and rear wheels, optimizing stability and control. This feature ensures that braking power is distributed evenly, preventing skidding or loss of control.

Feature Three

Brake wear indicator: Some brake systems come with wear indicators that alert the driver when the brake pads are worn and need replacement. This feature helps ensure timely maintenance and prevents brake pad damage.

Feature Three

Brake pad materials: Different brake systems may utilize various materials for brake pads, such as semi-metallic, ceramic, or organic compounds. These materials vary in terms of performance, durability, and noise levels.

- Non-metallic materials - these are made from a combination of various synthetic substances bonded into a composite, principally in the form of cellulose, aramid, PAN, and sintered glass. They are gentle on rotors, but produce a fair amount of dust, thus having a short service life.

- Semi-metallic materials - synthetics mixed with varying proportions of flaked metals. These are harder than non-metallic pads, more fade-resistant and longer lasting, but at the cost of increased wear to the rotor/drum which then must be replaced sooner. They also require more actuating force than non-metallic pads in order to generate braking torque.

- Fully metallic materials - these pads are used only in racing vehicles, and are composed of sintered steel without any synthetic additives. They are very long-lasting, but require more force to slow a vehicle while wearing off the rotors faster. They also tend to be very loud.

- Ceramic materials - Composed of clay and porcelain bonded to copper flakes and filaments, these are a good compromise between the durability of the metal pads, grip and fade resistance of the synthetic variety. Their principal drawback, however, is that unlike the previous three types, despite the presence of the copper (which has a high thermal conductivity), ceramic pads generally do not dissipate heat well, which can eventually cause the pads or other components of the braking system to warp. However, because the ceramic materials cause the braking sound to be elevated beyond that of human hearing, they seem exceptionally quiet